Inkjet Solutions introduces Thermal Transfer Overpinting and Large Character DOD Printers. It also provides services and maintenance solutions in addition to supply of consumables /spares for all equipments.

Thermal Transfer Overprinting (TTO)

High quality print— robust and durable

Thermal Transfer Overprinting (TTO) is another high resolution technology printing and coding solution used for marking flexible packaging and labels. The process involves the use of the printer with a ribbon bearing the thermal transfer ink. It is recommended for printing of expiry date, bar codes, logos and other information on food, pharmaceutical and healthcare products that typically employ flexible packs, semi-rigid plastic packs and conformal packaging. The looks are superior to other methods and this makes TTO better than hot stamping and roller coding. It can print on all flat surfaces. TTO features high resolution allowing for printing of small character size with inclusion of barcodes and 2D codes with high legibility.

Key features of Thermal Transfer Overprinting (TTO) systems:

- 7″ Onwards Touch screen print controller for easy operation

- Graphics editor for simple message creation and editing

- Zero periodic maintenance, giving very low total cost per code

- Free text placement and graphic editing charactertools

- Up to 450mm/second to match most line speeds at 300dpi

- Real time and date formats, automatic offset, counters, custom date and time formats, production shift and remote field population from database

- Barcodes, 2D codes and Logo

- Quick and simple mess free changeover of ribbon with minimum downtime

- Wide range of ribbon to meet the most demanding process

- LAN and USB interface for remote control and back-up

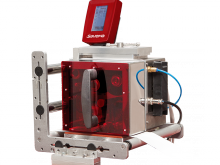

Large Character DOD Printers

When it is a requirement to print large sized characters on large packaging the preferred method is large character Drop on Demand (DOD) printing system. The printer incorporates a user configurable screen to input variables such as manufacturing/expiry date, batch number and codes. One can input shift code in the packaging printing operation. DOD printers can be installed on an existing conveyorized packaging system for ease of use.

Drop on Demand technology (DOD) is designed for both packaging applications and industrial marking solutions. Provides two different controllers depending on your application and have a variety of nozzle arrangements. They offer three base ink types; MEK for fast dry non-porous Food grade applications, Alcohol for food Grade applications, and Water for porous applications.

Our DOD printers can provide solutions for coding on a multitude absorbent and non-absorbent surfaces including:

Paper, Cardboard, Metal, Glass, Wood, Plastic, Rubber.

Key features of Inkjet DOD Large Character are:

Excellent print quality – high quality coding output delivered via proven solenoid technology; great print results on porous and non- porous.

- Low cost – extremely cost effective printing .

- Ease of use – Simple, robust design makes them easy to operate & maintain

- Flexibility – easy to configure up to 16 printheads to meet virtually any industrial printing need

- Durability – each DOD inkjet printer features a strong, stainless steel external casing which provides excellent protection from humidity, dust and high temperatures found in industrial environments